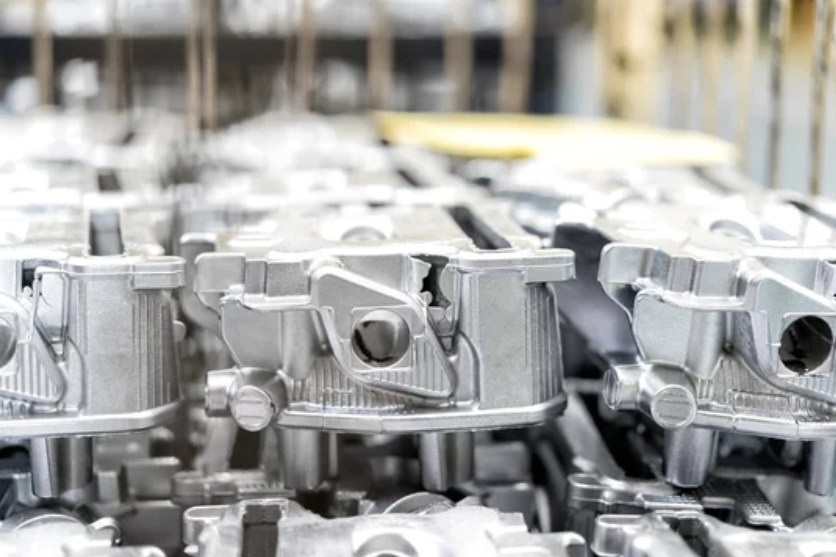

Exploring Aluminum Foundry operations that maintain top-tier casting results

A Comprehensive Overview to Selecting the Right Shop Solutions for Your Project Needs

Picking the right foundry solutions is important for the success of any kind of task. Each casting method-- sand spreading, investment casting, and pass away casting-- has unique benefits. Understanding these alternatives assists in making informed choices. Product choice, manufacturing abilities, and high quality assurance are essential aspects to take right into account. Furthermore, evaluating prices can affect long-term stability. Precision aluminum casting. What elements should lead this decision-making process?

Recognizing the Different Kinds Of Factory Providers

While the globe of factory solutions may seem facility in the beginning glimpse, understanding the numerous kinds can significantly enhance the manufacturing procedure. Shops typically concentrate on casting steels, and the main kinds include sand spreading, investment spreading, pass away casting, and centrifugal casting.

Sand spreading entails producing molds from sand and is suitable for huge parts or low-volume manufacturing. Financial investment spreading, on the various other hand, offers high precision for intricate layouts, making it ideal for aerospace or clinical applications. Pass away spreading, characterized by requiring molten metal into molds under high stress, is reliable for automation of smaller sized parts.

Centrifugal casting makes use of rotational pressure to disperse liquified metal, producing strong, cylindrical components. Each service type has distinct benefits and is chosen based on particular project requirements. Understanding these differences enables makers to select one of the most ideal shop solution, inevitably enhancing performance and item high quality.

Secret Factors to Consider in Product Choice

Choosing the proper product for shop services is an important step that influences the total success of a task. Secret aspects in product option consist of mechanical buildings, thermal resistance, and deterioration resistance - aluminum casting. Comprehending the intended application and its needs is essential; products should withstand operational tensions while keeping honesty gradually

One more crucial consideration is the material's compatibility with the picked production process, as some products are better fit for particular strategies. Cost-effectiveness likewise plays a considerable duty, as budget plan restraints can limit alternatives.

Finally, schedule and preparation of products can influence project timelines, making it essential for job managers to assess these factors completely. By meticulously examining these elements, one can ensure a much more effective and successful foundry service experience.

Assessing Manufacturing Capacities and Technologies

Just how effectively a foundry can meet task requirements rests on its manufacturing abilities and modern technologies. A detailed evaluation of these components is essential for task success. Manufacturing abilities encompass the factory's capability to manage varying task timelines, sizes, and complexities. Comprehending the factory's equipment and equipment is important, as contemporary innovations such as computer mathematical control (CNC) machining and progressed mold-making techniques can greatly boost accuracy and performance.

Furthermore, the factory's use ingenious materials and procedures, such as 3D printing or lost foam casting, can supply advantages concerning layout versatility and cost-effectiveness. It is likewise essential to evaluate the foundry's capacity to scale manufacturing, making sure that they can fit future increases sought after without compromising top quality. By carefully evaluating these factors, job managers can make enlightened decisions regarding which shop is best matched to meet their certain production needs and technical expectations.

Significance of Quality Control in Steel Spreading

Quality control stands as a vital column in the metal spreading industry, guaranteeing that every component fulfills rigorous specifications and requirements. This procedure entails systematic tracking and evaluation of each stage of production, from initial style to last examination. Applying extensive quality control protocols boosts the reliability and performance of cast elements, decreasing the probability of issues that can endanger architectural integrity.

Effective high quality assurance fosters count on between customers and shops, as adherence to high criteria symbolizes dedication to excellence. It also minimizes pricey rework and delays, streamlining production procedures. By recognizing possible concerns early, quality control not just safeguards the end product however likewise adds to continual renovation within the factory's operations. Inevitably, focusing on high quality guarantee in metal spreading is vital for accomplishing customer contentment and keeping an affordable side in the sector.

Reviewing Cost-Effectiveness and Spending Plan Restrictions

While traversing the intricacies of foundry solutions, examining cost-effectiveness and budget restraints emerges as a vital factor for services. Understanding the complete price of possession involves greater than just the first cost; it requires an evaluation of lasting costs, including materials, labor, and functional efficiencies. Firms need to ask for detailed quotes that detail all potential prices, making it possible for a clearer contrast in between different shops.

Additionally, services must examine their details project needs versus websites spending plan constraints. This includes assessing the trade-offs in between lower expenses and possible influence on top quality, lead times, and dependability. It is essential to think about whether the chosen shop offers scalable services that can suit future demands without significant monetary stress. By carefully balancing cost variables with task objectives, companies can make informed choices that optimize both budget plan and performance, making sure effective results for their shop tasks.

Frequently Asked Questions

Exactly How Can I Ensure Timely Shipment of My Shop Task?

What Accreditations Should a Factory Provider Have?

A reputable foundry company must possess certifications such read this post here as ISO 9001 for top quality administration, ISO 14001 for environmental administration, and industry-specific certifications that show compliance with safety and security and performance standards appropriate to the casting procedure.

Can I Go To the Shop Before Choosing?

Yes, going to the shop before choosing is typically advisable. This enables prospective clients to examine the center, meet the group, and warranty that the services straighten with their specific job demands and requirements.

What Is the Common Preparation for Customized Castings?

The regular lead time for personalized castings varies from four to twelve weeks, depending on the intricacy of the layout, material specs, and the shop's capability. Prompt communication can usually accelerate the procedure.

Exactly How Do Shops Deal With Layout Adjustments During Production?

Factories typically fit layout adjustments during manufacturing by applying adaptable procedures. They evaluate the effect on prices and timelines, connect with customers, and readjust operations to guarantee high quality while visit site decreasing disturbances to the manufacturing schedule.